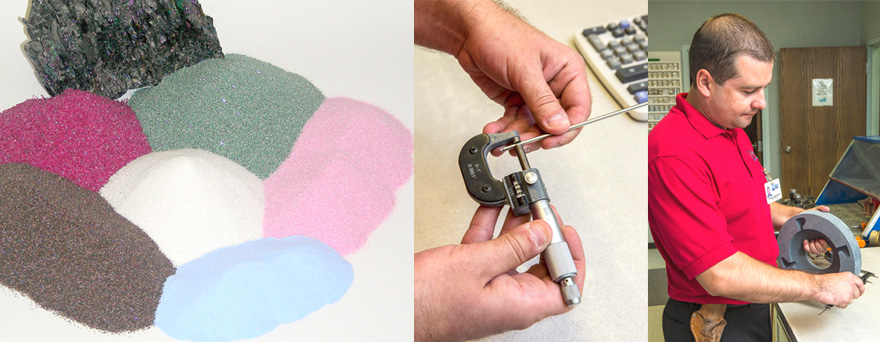

Abrasive Grain

There are many factors involved in matching an abrasive to an application. The information contained herein relates to typical conditions, however, there are endless combinations of these factors. GRIER’s experience will be an important ingredient to assist in matching abrasive to application. Listed below are some of the important ingredients to proper selection. To make bonded abrasives, you need (1) abrasive grain and (2) bond. To get specific properties, GRIER selects the appropriate (3) grade, (4) structure and (5) treatment.

Bonds

The Bond used in producing abrasive product is what holds the abrasive grains together and has no cutting capabilities of its own. GRIER manufactures product using vitrified, resin, and latex bonds. Vitrified bond is a glass or ceramic bond which is very hard and comparatively brittle. There are various vitrified bonds that are used to obtain certain desired results or to meet required standards. GRIER manufactures vitrified product in 11, 13, 22, 31, 41, 51, and 55 bonds. Resin bond is a strong, tough, resilient material. It absorbs shock better than vitrified. It is used for fast stock removal and is popular with foundries with off-hand operations. It works well on stainless steel, brass, bronze, and aluminum. Latex bond is the bond utilized by GRIER in its soft Griertex product.

Grain Size

Abrasive grain comes in a wide variety of grain sizes. For rough grinding and heavy stock removal coarse grit sizes are used, while fine grit sizes are used for work where a finer finish or a desired shape is necessary.